Expert Plant Engineering Services & Factory Engineering Solutions for Efficient Operations

Plant Engineering Services & Factory Engineering Solutions | Optimized Industrial Design

About VDC Tech

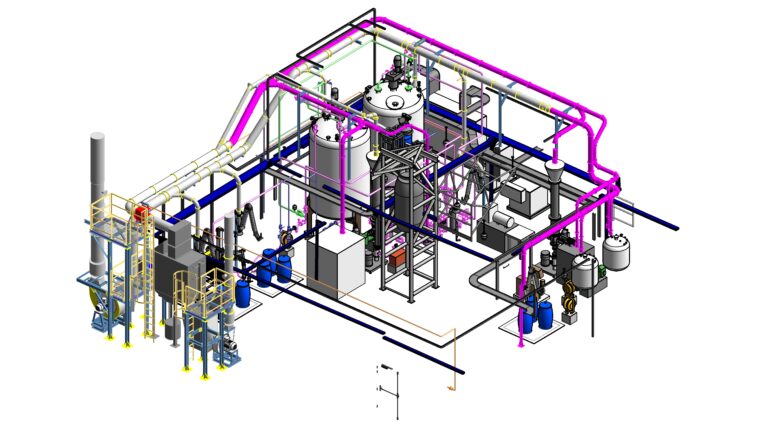

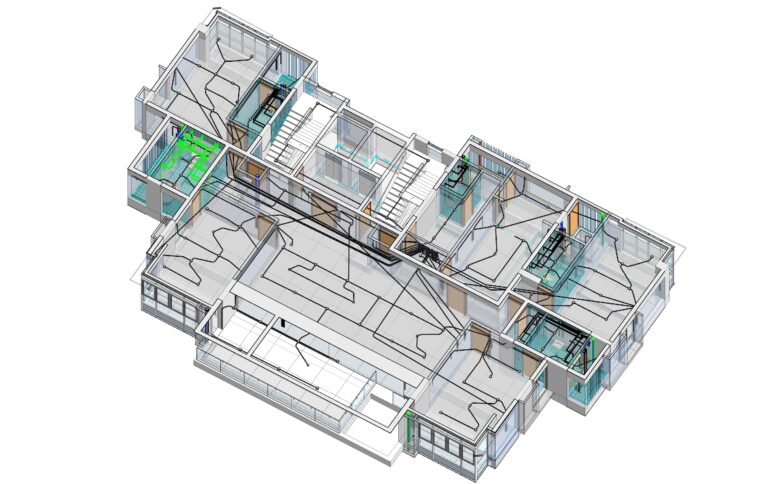

VDC TECH engineering solutions provides to create an accurate specification’s, Designs options for Process plant, selection of effective Equipment’s, accurate cost estimation, reusability of drawings/specs, design review process and accurate of reports. Usually in process engineering, Engineers spend a lot of time in creating drawings and generating CAD outputs instead of focusing on their core (Plant Engineering Services, engineering/design) activities. VDC TECH engineering assists an organization in creating such CAD outputs using intelligent tools such as Plant 3D and Revit. It helps companies to create a knowledge repository and create (process) design options based-on the inputs received from customers. We help in sizing of utilities based on preliminary inputs along with using various latest tools. We deliver the intelligent outputs (deliverables) and assist our clients in management of the change across the project life-cycle. Whether it is converting legacy data into digital & intelligent formats or updating existing assets as per operating condition (for e.g. uniformity in Tagging standards), or assistance in creating design options for design review; VDC TECH work as an extended arm of our client’s engineering team and provides flexibility and scalability for faster turnaround of designs.VDC TECH engineering knows about the challenges and with respective to it provide comprehensive solutions for Plant Piping from design (spec. creation, sizing calculations, catalog creations, etc.) , 3D modelling (using various software platforms such as Plant 3D, Revit), IFC – Construction deliverables (GA drawings & Isometrics), Piping Analysis (flexibility analysis) and extracting intelligent reports (pipeline list, MTO’s, etc.). Our team of experts have experience across industries such as Oil & Gas, Chemicals & allied industries, Pharmaceutical, Food & Beverages and Utilities such as Water & Effluent Treatment, Renewal Energy and Power.

Key service Offerings

• Intelligent (spec-driven) Piping and Instrument Diagrams based on preliminary PFDs

• Heat and Mass Balance Diagrams

• Water Balance Diagrams

• Hydraulic Analysis – Pipe Sizing & Pressure Drop Calculation

• Line List & Equipment List.

• Piping Design Basis.

• Piping Material Specifications.

• Mechanical Static Strength Calculations & Equipment Sizing

• Electrical Equipment Sizing/Optimization using ETAP

• Civil & Structural Design Optimization

• Indicative Plot Plan & General Arrangements.

• Technical Specifications & Datasheets of Various Equipment’s

• Legacy data conversion (old P&IDs to smart P&IDs)

About VDC Tech

VDC TECH engineering has deep experience about the different type of country codes, standards and specifications for Plant Piping and Layout creation. Our team knows about to create an error-free and clash free layout’s in order to create an accurate BOMs/BOQs. Our team usually do an QC of data consistency checks in order to avoid iterations. Our team has an good understanding of various load cases for piping flexibility analysis and pipe rack design.

VDC TECH engineering knows about the challenges and with respective to it provide comprehensive solutions for Plant Piping from design (spec. creation, sizing calculations, catalog creations, etc.), 3D modelling (using various software platforms such as Plant 3D, Revit), IFC – Construction deliverables (GA drawings & Isometrics), Piping Analysis (flexibility analysis) and extracting intelligent reports (pipeline list, MTO’s, etc.). Our team of experts have experience across industries such as Oil & Gas, Chemicals & allied industries, Pharmaceutical, Food & Beverages and Utilities such as Water & Effluent Treatment, Renewal Energy and Power.