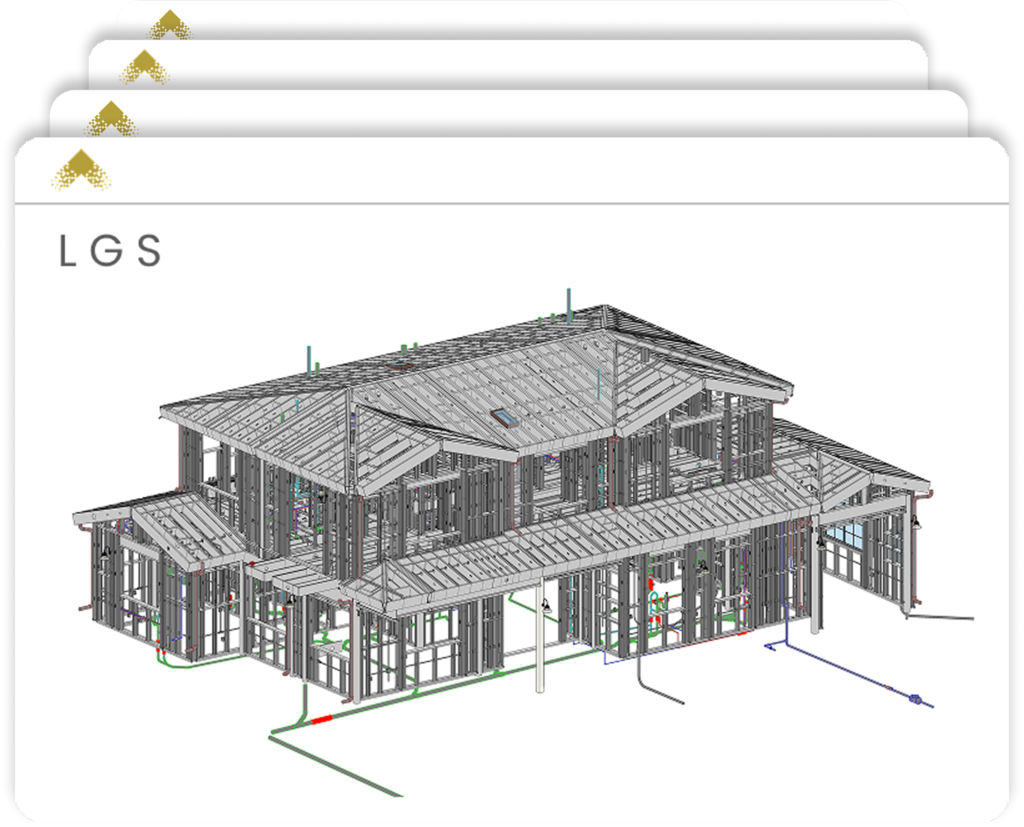

LGS BIM Modeling and Engineering Excellence

Client Overview

- Our Client approached to us with challenging project to design and engineer a state-of-the-art light gauge steel structure for a Multi-family house ( town house) in the USA. The project had several complexities, including:

The Challenges

Using integrated BIM systems, we enable smooth cooperation between project stakeholders such as architects, engineers, contractors, and fabricators. This provides effective communication and collaboration throughout the project’s lifespan.

- Tight deadlines of two weeks

- Complex architectural design

- Integration of LGS with MEPF services

- Compliance with local building codes and regulations specially for cladding work

- To complete LGS modelling within 2wees of timeframe.

Our Approach

- Initial Assessment and Planning: Conducted a detailed site assessment to understand the project requirements , constraints and objectives.

Collaborated with our client to define project goals, scope, and deliverables. - Innovative Technique Using BIM: Utilized BIM software (e.g., Autodesk Revit + MWF) for 3D modelling, clash detection & resolution along with MEPF services.

Integrated BIM with advanced analytic tools to optimize material usage, reduce waste, and enhance structural performance

Adopteda collaborative BIM approach, enabling real-time collaboration and communication among architects, engineers, and contractors. - Engineering and Design: Developed detailed engineering drawings, spoecifications, and calculations in compliance with local building codes and regulations.

Implemented innovative design solutions to address complex architectural requirements and ensure structural integrity.

Conducted rigorous simulations and analyses to validate the design, optimize performance, and mitigate risks. - Project Execution and Management: Establish a dedicated project team comprising experienced engineers, architects, and project managers.

Implemented agile project management methodologies to monitor progress, track milestones, and manage changes effectively.

Maintained open communication channels with our clients to provide regular updates , address concerns, and solicit feedback.

End Result LGS BIM Modeling

- Design Optimization: We reduced the steel weight from the planned 35 to 32 tones, eliminating the need for Hot roll steel sections.

- Time Optimization: Our innovative BIM technology pinpointed punch hole locations in the shop drawing, saving approximately 100 hours of assembly labor compared to traditional on-site punching.

Utilized Revit software optimally to assure streamlined coordination with MEP services, this helped in shortening shop drawing creation time.

Conclusion:

- Our firm’s innovative approach, expertise in BIM technologies, and commitment to excellen ce enabled us to overcome the challenges associated with the engineering, modeling, and designing of the light gauge steel project for our clients.

- By leveraging advanced technologies, adopting collaborative methodologies, and focusing on delivering value-added solutions, we not only met but exceeded client expectations, demonstrating our capabilities and reinforcing our position as a leader in the engineering and design industry